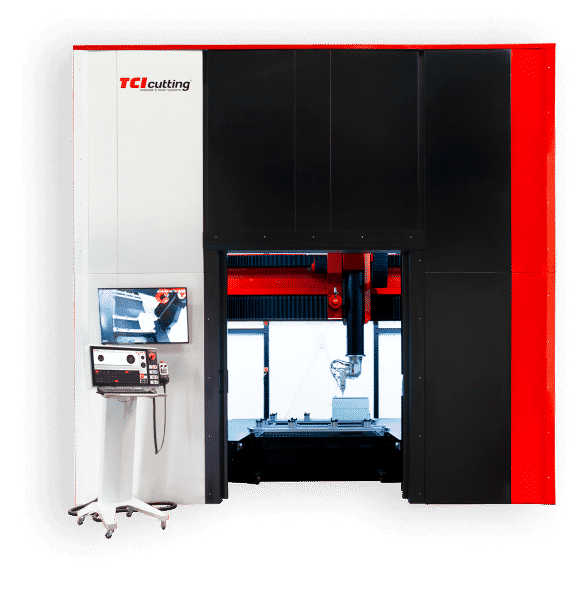

3D XXL Cutting

TCI Cutting Dreamline Fiber® opens up a whole new world of 3D production possibilities with 5-axis laser cutting. A fully robotic system with which the production of complex cuts becomes a simple task. The powerful bridge that houses the 3D cutting head, enables the creation of cutting programs with multiple angles for the same piece, an acceleration of more than 1G and with powers from 1 kW to 4 kW. The 900 mm travel of the Z axis offers endless possibilities.

Fiber laser source technology is responsible for producing production series at high speed and at a minimum cost, this system being one of the most complete and intelligent on the market. Its connectivity with digital systems generates an unmatched production flow.

Versatility and infinity of configurations, make the Dreamline Fiber® a machine capable of adapting to the needs of any sector with the option of customization, milling and threading options with 3D rotation.

Option: Production Management Intelligent Software for autonomous and strategic decision making.

Optimize your cutting machine and gain competitiveness.

Technical specifications

| Feature | |

|---|---|

| Maximum load | 600 kg |

| Heads | 1 (5 axes) |

| Maximum simultaneous positioning speed | 85 m/min |

| Maximum axial acceleration | 1G |

| Machine tolerance VDI/DGQ3441 | ± 0.05 mm/m |

| Repeatibility | ± 0.025 mm |

| Power output | From 1 kW to 4 kW |

| Dimensions | 3.000x2.400x900 mm |

| Axes (X, Y, Z) | 3.000 x 2.400 x 900 mm |

| Gap Dedicated Axis (W) | Inclusive |

| Measurement System | Optical absolute rulers (Optional) |

HIGH PRODUCTIVITY

Smart features

LASER CUTTING MACHINES

Technological developments

Energy Cut Gas Mix 2.0®

Up to 70% reduction of gas consumption in oxygen and nitrogen cutting.

Rage Cut 2.0®

40% faster high power laser cutting on thick carbon steel parts.

Fly Cut 3.0®

Ultra fast cutting in grid and consecutive drills.

Nozzle Control 2.0®

Diagnosis of nozzle condition using artificial intelligence.

Smart Camera 4.0®

Intelligent camera for material detection and measurement.

Freezetec 2.0®

Water-cooled laser cutting system.

AUTOMATION

Automated systems

Automation Systems®

Twin Table

Automation solutions for the loading and unloading of parts.

Benefits

Why

TCI Cutting

Autonomous decision making.

BE PART OF THE FUTURE

Clients around the World

Download technical sheet

Dreamline Fiber®

Download the complete catalogue of our solutions