The Spaceline and Dreamline laser cutting machines, from the Valencian company TCI Cutting, stand out for offering the market cutting-edge technological solutions in intelligent 3D laser cutting, with infinite turns and an inclination of up to 135 °.

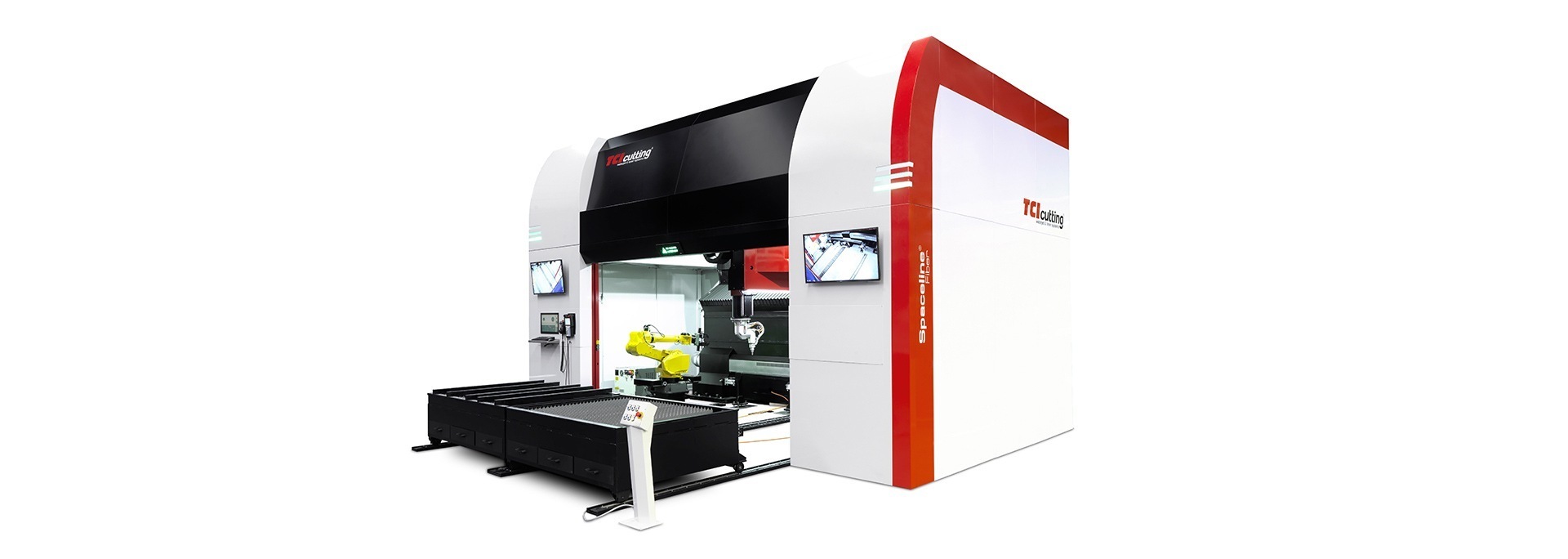

Specifically, the Spaceline Fiber cutting machine offers the possibility of including a robotization system that facilitates the production of very complex cuts, by repositioning the piece at the correct angles in different stations or repositioning cradles. This 6-axis machine, that is to say, 5 interpolation axes in space, plus a sixth additional axis for following the focal cut, is characterized by its type of arm-type structure, which houses the cutting head. Its acceleration of more than 1G and a power that can go up to 6 kW, make it possible to create cutting programs with multiple angles for the same piece. On the other hand, the 700 mm travel of the Z axis offers infinite possibilities for cutting, both with the robot or on the worktable. The kinematics of this arm-type machine, supported by the replacement of a robot in the cutting part, make accessibility to the cutting table total and allows intelligent automation, within a productive chain without stops and fulfilling productive cycles as demanding as in the automotive sector.

It is therefore the right machine to perform complex and repetitive 3D cuts within a production process.

As for its twin sister, the Dreamline, its great advantage lies in its modularity on the one hand, and in its ability to target the large format segment, X axis 3,000 mm and Y axis up to 12,000 mm, with a travel of up to 900 mm of the Z axis. In other words, since the cutting head is on a bridge in Gantry mode, it allows cubic dimensions to be interpolated in space at the customer’s need, offering extraordinary flexibility in 3D laser cutting.

In the case of the Dreamline, the loading and unloading of materials to be cut is carried out by means of two mobile tables, which allow the piece to be cut to be placed in a cradle designed by the client, and through it, an origin of the piece is established , with respect to the interpolated coordinate system of the spindle cutting. These tables enter the 3D cutting machine, alternatively one with respect to the other, allowing the cutting process not to stop for positioning reasons.

In both cases, its connectivity with intelligent production management software for autonomous decision-making allows the creation of a Smart Factory within an industry 4.0 environment. no production stops.