Automation

Increased productivity,

speed and customisation

Intelligent automation as part of the new era with direct impact in the production process.

Greater productivity, speed and customization. Factories interconnected digitally thanks to production management intelligent software for autonomous and strategic decision making (Manager PRO®). The future of the cutting sector or the cutting sector of the future?

MOTORIZATION OF PARTS WITH ROBOT

Automation Systems®

The motorization of parts with robot is a highly automated solution highly productive and efficient that streamlines and improves the production process. Programming of variable trajectories for the accomplishment of diverse tasks. Without errors.

- Nominal sheet size: 3000 x 1500 mm

- Nominal sheet size: 3000 x 1500 mm

- Maximum weight of the sheet metal 750 kg

Which machines can I use the Automation Systems Laser Robot® with?

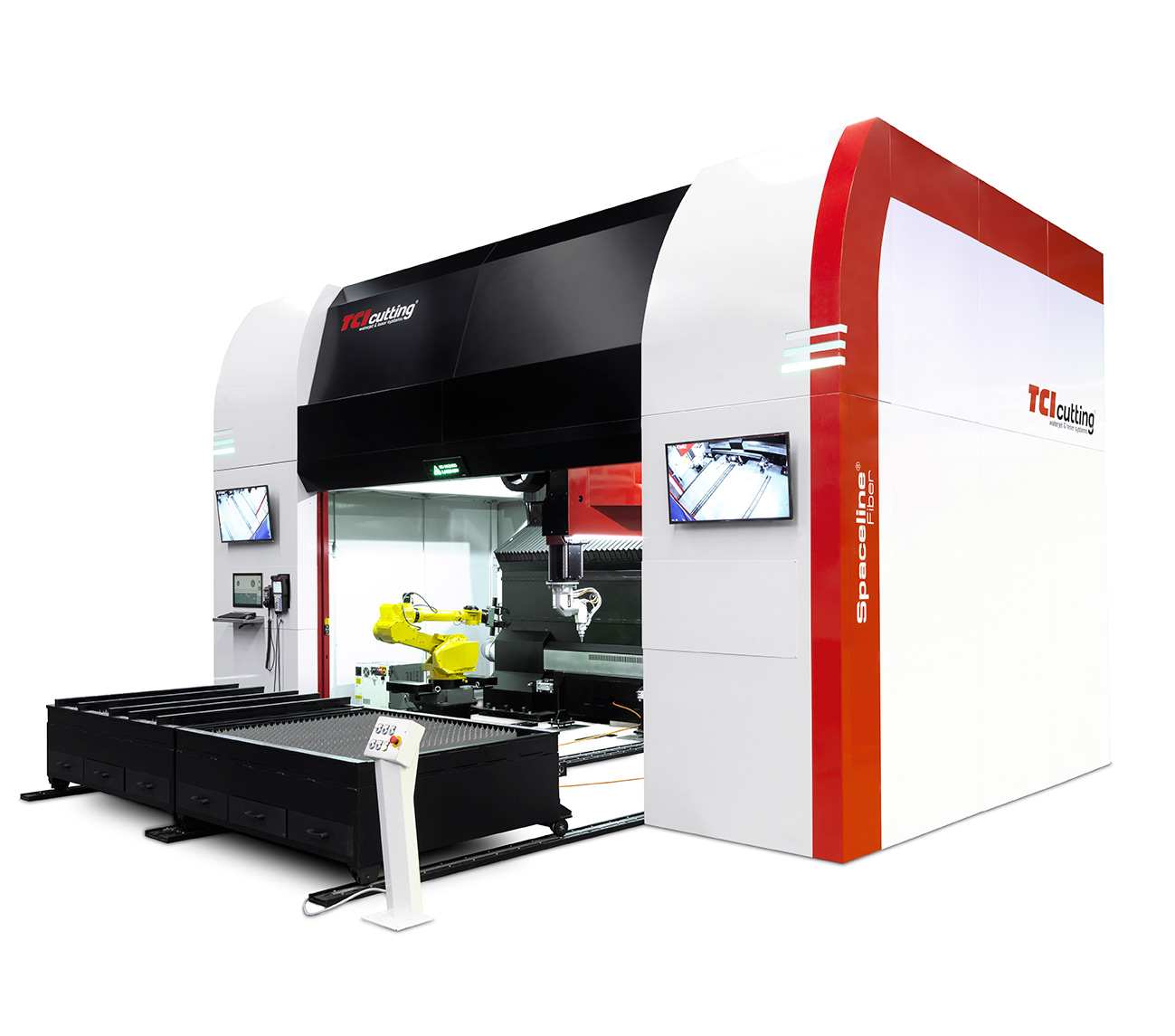

AUTOMATED 3D CUTTING

Spaceline Fiber®

MOTORIZATION OF LOADING TABLES

Automation Systems®

Both, the automation solution with interchangeable table or with spin table allows loading and unloading of parts while cutting machine is still active.

In addition, the spin table saves space in factory , really important for our customers. Both automations increase productivity and competitiveness in factory and represent a breakthrough technology that optimizes the production process thanks to the combination of tasks that occur at the same time, thus reducing the production cycle and increasing efficiency rates.

With which machines can I use Automation Systems Twin Table®?

AUTOMATED 3D CUTTING

Spaceline Fiber®

3D CUTTING XXL

Dreamline Fiber®

Benefits

Why

TCI Cutting

Autonomous decision making.

BE PART OF THE FUTURE

Clients around the World

Download data sheet