Productivity in its purest form

For large series and volumes, without losing sight of electrical and production efficiency. With high power versions and the possibility of cutting thicknesses up to 50 mm, being able to reach a maximum acceleration of 4G.

Maximum acceleration and cutting power at your fingertips. Its design includes a carbon fiber bridge, linear motors and double, front and side accessibility. 2D cut. Travel speeds of up to 280 m/min guarantee the highest productivity for the most demanding long series customers.

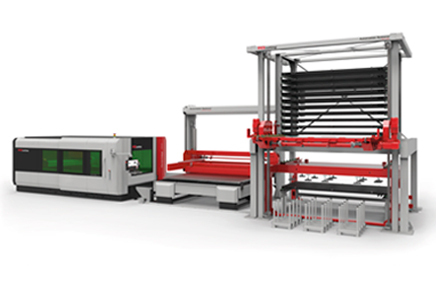

Tailor-made intelligent automation option for simultaneous loading and unloading, intelligent storage and parts smart sorting with palletization and Intelligent Production Management Software for autonomous and strategic decision-making. Optimize your cutting machine and gain competitiveness.

Technical specifications

| Feature | 1530 | 2040 |

|---|---|---|

| Maximum load | 950 kg | 1.800 kg |

| Heads | 1 | 1 |

| Maximum simultaneous positioning speed | 280 m/min | 280 m/min |

| Maximum axial acceleration | up to 4G | up to 4G |

| Machine tolerance VDI/DGQ3441 | ± 0.05 mm/m | ± 0.05 mm/m |

| Repeatibility | ± 0.025 mm | ± 0.025 mm |

| Power output | Power according to need | Power according to need |

| Dimensions | 1.500x3.000x100 mm | 2.000x4.000x100 mm |

| Fully enclosed and cabined machine | Included | Included |

| Smoke extraction system | Incluido | Included |

| Cooling system | Included | Included |

| Automatic table exchanger | Included | Included |

| Automatic loader and unloader | Optional | Optional |

| MODELS | Dimensions |

|---|---|

| 1530 | 1.500x3.000x80 mm |

| 2040 | 2.000x4.000x80 mm |

HIGH PRODUCTIVITY

Smart features

LASER CUTTING MACHINES

Technological developments

Energy Cut Gas Mix 2.0®

Up to 70% reduction of gas consumption in oxygen and nitrogen cutting.

Rage Cut 2.0®

40% faster high power laser cutting on thick carbon steel parts.

Fly Cut 3.0®

Ultra fast cutting in grid and consecutive drills.

Nozzle Control 2.0®

Diagnosis of nozzle condition using artificial intelligence.

Smart Camera 4.0®

Intelligent camera for material detection and measurement.

Freezetec 2.0®

Water-cooled laser cutting system.

Automation

Automated systems

Automation Systems

Smart Cell®

Simultaneous loading and unloading, storage and parts smart sorting with palletization.

Automation Systems

Load & Unload Storage®

Simultaneous loading and unloading and storage

Automation Systems

Compact Load & Unload Storage®

Loading and unloading in the same movement with a short exchange cycle.

Automation Systems

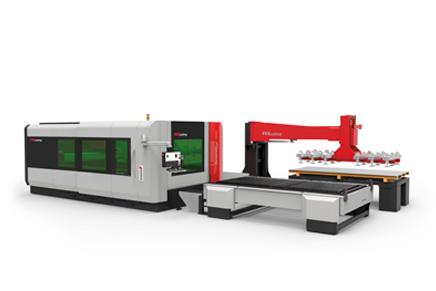

Load & Unload®

TCI Loader & Unloader BRG 3.0 is the automation solution that best optimizes material flow.

Automation Systems

Bridge Load®

Intelligent solutions for loading in laser cutting facilities.

Automation Systems

Arm Load®

Intelligent solutions for loading in laser cutting facilities.

Benefits

Why

TCI Cutting

Autonomous decision making.

BE PART OF THE FUTURE

Clients around the World

Download technical sheet

Dynamicline Fiber®

Download the complete catalogue of our solutions