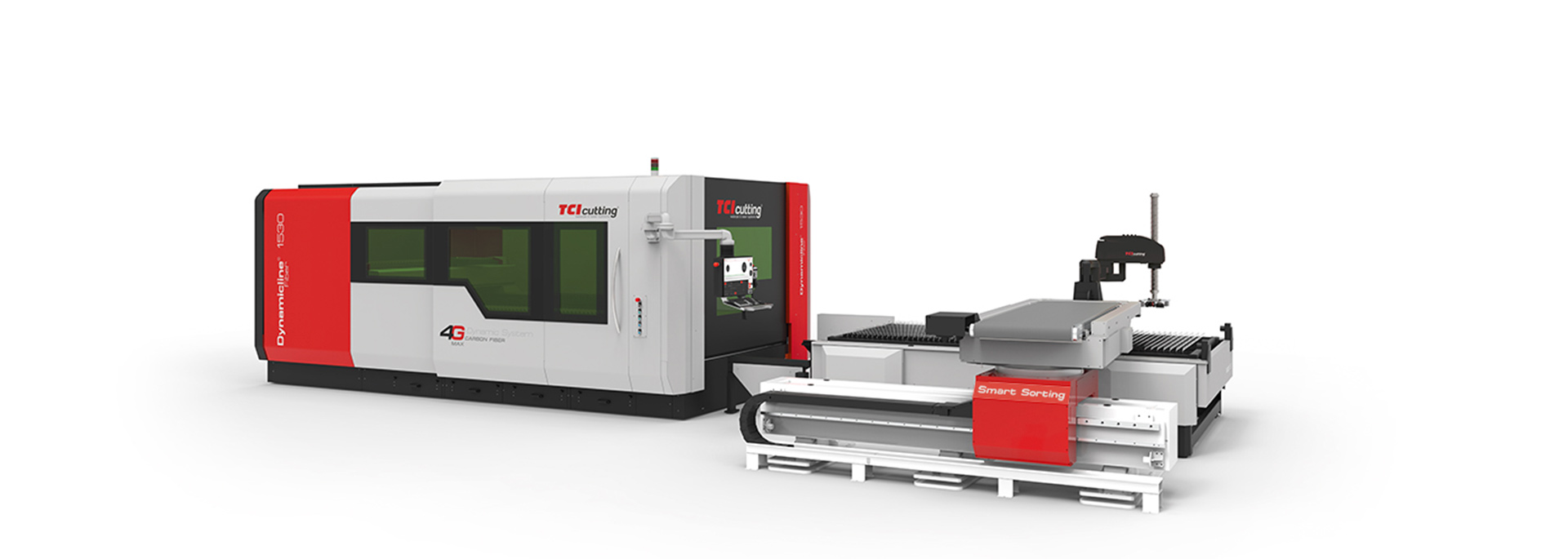

TCI Cutting’s 2D laser and tube cutting machines incorporate different automation solutions as they streamline, improve and systematize post-cutting processes.

Our solutions are developed by experts with an adaptive approach to customer needs and allow a clear saving of space in factories, restructure cutting companies in an integrated ecosystem of the production process and incorporate advances such as Automation Systems Smart Sorting, the smart classification system of TCI Cutting. Their scalability allows the integration of advanced systems with robots to achieve highly intelligent production units, Smart Cells, developed by the Spanish company and which are connected to each other by self-guided vehicles.

Specifically, Automation Systems Smart Sorting classifies the cut pieces for their subsequent automatic distribution among the different complementary processes to the cut. This solution ensures optimal planning, order and control within the factory, as well as better time and business resources efficiency.

Unlike other manufacturers, the robot and the automatic unloading do not need to be programmed by the operator thanks to TCI Manager, the intelligent production management software for autonomous and strategic decision making, which allows the nesting to recognize the parts automatically and decide autonomously which tool is necessary for each part.

Consequently the activity of the cutting machine increases and also the productivity ratio, both of the machine and the company, with the goal to reach factories without errors.

The parts can be classified by the order commanded by TCI Manager or by the one indicated by the cutting operator. Finally, they can be palletized in boxes, derived to robots or distributed by self-guided vehicles, among others.