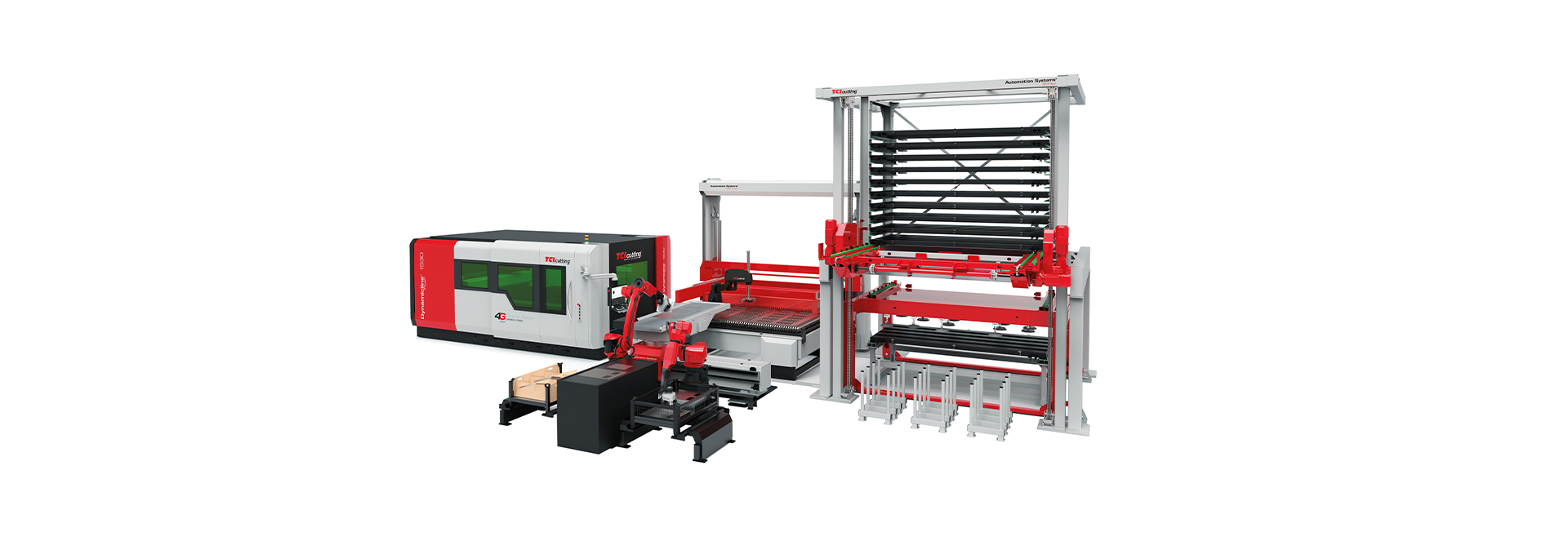

TCI Cutting integrates the parts smart sorting and its subsequent palletizing system into its automated production cell. This integral solution allows a fluid speed of the entire production process of cutting, simultaneous loading and unloading, storage, parts smart sorting and palletizing. Later the palletized parts can be transported by AMRs (autonomous mobile robots) to bending, welding or other processes, depending on the production cycle in the manufacturing plant.

The implementation of this automated solution, Automation Systems Smart Cell®, increases the autonomy of the factory, reduces operating costs and redirects the workforce towards non-recurring and highly productive tasks. This solution is developed according to the production process and needs of each customer, in its factory in Valencia. This ensures the seamless integration of all processes in this automated solution.

The communication of parts smart sorting and palletizing with the laser cutting machine is carried out through the software Manager PRO software, of self development. Nesting changes do not require a reprogrammer engineer as the software itself assigns the order for each part according to its destination in the production line.

The automated sorting and palletizing of parts increases workplace safety in the factory, and can combine the handling of large and small parts. Small parts are stored and palletized off the cutting line so that the machine continues to work without interruptions.

This integral solution is adaptable to the laser cutting machine Dynamicline Fiber®, 2D cutting, and specially developed for large volumes 24×7 hours, which guarantees maximum productivity throughout the entire production cycle in a digital and autonomous factory environment.

TCI Cutting with factory and showroom in Valencia (Spain), is a world benchmark in the manufacture of laser and water cutting machines, tailor-made and scalable intelligent automation systems, as well as smart production management software for autonomous and strategic decision making and accompanies its customers in their digital transformation processes and optimization of their cutting factories on their way to a Smart Factory.