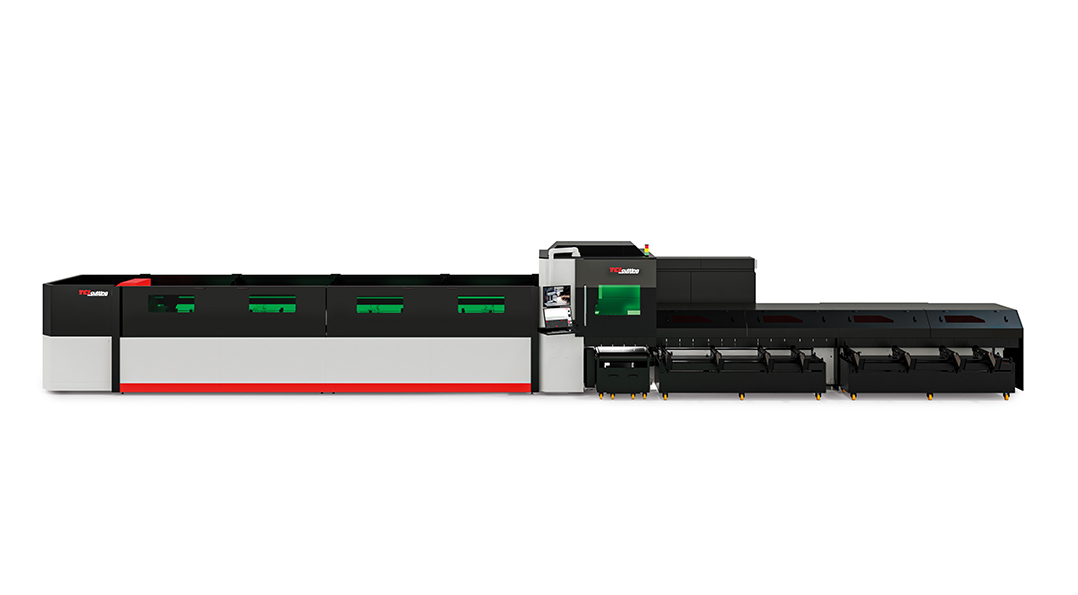

TCI Cutting launches the new version of its Smarttube Fiber® laser cutting machine for tubes and profiles. High flexibility and autonomy in cutting all types of tubes and profiles, open and closed, from 20 to 220 mm, without having to change the tooling. This is a great competitive advantage by increasing the machine’s operating time and ensuring that the production process in the factory does not stop.

With automated loading and unloading, its new design not only increases the speed and flexibility of the machine but also minimizes the waste of cut material.

The machine has an automated loading and unloading system for its total autonomy with a clear increase in productivity, speed and efficiency.

Smarttube Fiber® has two head options, 2D (flat cut) or 3D (bevel cut). Its cutting achieves perfect finished parts with complex shapes, and eliminates the processes needed without a laser cutting machine. This improves customer response times and ensures high-end cutting quality.

This technology guarantees the highest productivity, precision, cost-effectiveness and flexibility in both small and large series, with a maximum loading length of 12 m and discharge of 6 m. The machine also has a welding detection system by means of an intelligent camera.

This solution is perfect for multiple sectors such as industrial machinery, commercial vehicles, energy, construction, decoration or automotive, among others. Laser cutting technology for tubes and profiles has opened up new fields of application in many sectors thanks to its automation.

TCI Cutting, based in Guadassuar (Valencia, Spain), is a world referent in the manufacture of laser and water-jet cutting machines, customized and scalable automation systems, as well as intelligent production management software. The Company supports its customers in their digital transformation processes and optimization on their way to a Smart Factory.